Infineon sensors make buildings smarter, more environmentally friendly, and more energy-efficient

In the future, more and more people will live in cities. According to United Nations projections, by 2022, 56% of the world’s population will be urban residents; by 2050, this number will rise to 68%. This means that we must use existing resources more efficiently, while at the same time we must reduce overall energy consumption and carbon dioxide emissions.

Buildings can play a decisive role in solving this challenge. In the European Union alone, 40% of energy consumption and 36% of carbon dioxide emissions are caused by buildings. According to the assessment, 75% of the existing building stock in the EU has the problem of inefficient use of energy. This obviously indicates that there is huge room for improvement in building energy efficiency.

As a result, the European Union has revised and agreed on a series of rules and requirements in its “Building Energy Efficiency Directive”, which requires EU member states to approve the implementation of national policies aimed at improving the energy efficiency of the construction industry.

The directive specifically pointed out that smart building technology is a key element to achieve the goal of improving energy efficiency. Smart sensor technology, which has proven its advantages in Industry 4.0, is now being used to realize building automation. Intelligent building automation and control systems can significantly improve the efficiency of building operations through the data collected by sensors. A set of indicators that can show the conditions of the intelligent transformation of buildings is also being established. This set of indicators can be used to evaluate a building’s ability to use new technologies and Electronic systems to reduce energy consumption and emissions, and to adapt to the needs of occupants.

Improved energy efficiency is not the only benefit that smart buildings can bring. Intelligently installed sensors and actuators can continuously monitor and adjust air quality and lighting settings to ensure the best working environment, increase production efficiency, and maximize living comfort.

The “The Edge” office building in Amsterdam is the best example of how smart technology can cut building operating costs and increase production efficiency. This 40,000-square-meter office building is equipped with approximately 28,000 sensors, enabling the building management system (BMS) to collect information on key parameters such as humidity, temperature, and brightness. The BMS then automatically triggers the adjustment of the building’s operating conditions according to the changes of these parameters, so as to ensure that the heating, ventilation and air conditioning (HVAC) system, lighting system and other various systems can operate as efficiently as possible. Therefore, the power consumption of “The Edge” office building is 70% lower than that of traditional office buildings, making it one of the most energy-efficient smart buildings in the world.

Although the “The Edge” project is still relatively rare today, the smart building market is undoubtedly on a rising trend. According to recent market research and forecasts, by 2022, the smart building equipment market will double at a compound average growth rate (CAGR) of 16%.

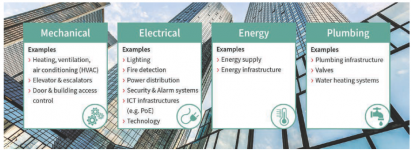

Figure 1: Elements covered by smart buildings

Smart buildings: make buildings smarter, more environmentally friendly, and more energy-efficient

Figure 2: The level of intelligence of smart buildings

What is a smart building?

Smart buildings are different from smart homes and specifically refer to non-residential buildings such as office buildings, shopping malls, and hotels. The devices in these buildings are connected to sensors that can provide in-depth consumption information and automatically make decisions to optimize operations.

The smart downlight that Infineon plans to exhibit at this year’s Frankfurt International Lighting and Building Technology and Equipment Exhibition is the best example. The downlight combines power and sensor solutions, allowing building managers to fully control the operating conditions of the building. In this system, the XDPL8221 digital control chip can monitor the relevant error conditions on the LED drive side, such as undervoltage, overvoltage, open load or output short circuit, etc. The 24GHz radar sensor can detect whether there are people in the building and count how many people there are, so that the system can dim the lights when there is no one to save electricity. The sensor can also send these data to the BMS system and the building manager for further analysis and optimization.

Following the more abstract action of “sensing, computing, and driving”, a series of networked sensors will collect environmental information, as well as data related to the operation and usage of the building. This information can be processed at the edge (edge computing) or sent to a central BMS system running locally or in the cloud. This information is then used to trigger automatic operations to make adjustments to the HVAC system, lighting system, blinds, and many other equipment in the building.

By using sensors, actuators and controllers to establish cross-connections between different subsystems, buildings can be “intelligent” (Figure 1). If the interconnection is compared to the skeleton of a smart building, then the actual equipment and control devices are equivalent to the muscles and brains of the building.

This interaction between smart components makes it possible to control the ventilation system based on indoor air quality (IAQ) and indoor carbon dioxide concentration (for example). The lighting system can also be adjusted automatically according to additional factors such as presence of people and indoor brightness. This can significantly reduce energy consumption while improving the comfort and well-being of users.

Intelligent buildings can be divided into three levels (Figure 2):

· Entry level, that is, there are only basic connections between the various subsystems of the building and the building management system;

· Intermediate level, which can comprehensively manage and control multiple integrated subsystems, including sensor-based data collection;

· Comprehensive level, that is, the ability to comprehensively manage and control all subsystems through intelligent coordinated actions between different subsystems.

There is no doubt that today’s buildings cannot reach the full level of intelligence overnight. On the contrary, it requires our small steps of accumulation and progress every day. Next, we will use Power over Ethernet (PoE) and condition monitoring as two examples to describe how to increase the level of intelligence in buildings.

Smart buildings: make buildings smarter, more environmentally friendly, and more energy-efficient

Example 1: POE as the hub of the interconnected system

The key to intelligent building is that large bandwidth and mass data transmission can be carried out between the subsystem and the BMS. Therefore, having a powerful and reliable information and communication technology (ICT) infrastructure is of the most core significance to any smart building.

The application of network connections based on the Internet Protocol (IP) in the industrial and residential fields has been quite mature. It is easy to install and maintain, can perfectly match the existing platform, and can be implemented with hardware and software. But Ethernet has a disadvantage, that is, devices connected to the Ethernet still need a separate cable to obtain power from the grid.

With the promulgation of the first generation of Power over Ethernet standards for Class 1 and Class 2 devices by the IEEE, this challenge for low-power devices such as IP phones and conference systems has been overcome. With PoE, power supply equipment (PSE)-such as PoE switches-can provide power and connections to many connected powered devices (PDs) through twisted pair Ethernet cables. This makes it necessary to establish only one physical connection—that is, an Ethernet socket (socket), and the physical connection can be completed independently by IT experts. This method can also reduce wiring work and simplify equipment management, thereby reducing installation and operating costs.

Until recently, PoE technology could only power devices below 30 W, which hindered its widespread application. As IEEE promulgated the 802.3bt standard in September 2018, Category 3 and Category 4 PoE devices can use all four twisted pair Ethernet cables, increasing the usable power of each port to 100 W. This opens the door to higher-power applications for PoE, such as 5G small base stations, LED lamps, high-power Wi-Fi access points, and public address (PA) systems powered by PoE.

The revised version of the standard also relates to overall energy efficiency, that is, reduced standby power consumption, and introduced a protocol for managing available power in a more granular manner according to power levels. However, these regulations pose new challenges to the design of switching power supplies (SMPS) for PoE devices.

First of all, in order to fully support the latest standards, a power budget of up to 100 W/port must be added to the PoE switch on the PSE side. In order to avoid the need to increase the size of the SMPS, the power density of the SMPS must be increased. This means that in the PSE design, the main SMPS must meet the key requirements of efficiency, power density, and reliability.

Secondly, a suitable semiconductor solution is needed to match the corresponding SMPS topology (such as flyback active clamp[ACF]or LLC). Choosing an efficient and reliable solution, such as Infineon’s super-junction CoolMOS™ MOSFET, can maximize the available power and extend the life of the device. Due to their high efficiency, energy consumption can also be reduced.

Efficiency, cost-effectiveness and power density play a crucial role in the isolated DC/DC SMPS conversion stage of PD. Every watt of power saved by improving the overall efficiency of the SMPS can be used by the PD itself.

When combined with reliable and efficient semiconductor solutions (such as Infineon’s OptiMOS™ and StrongIRFET™ product series for PD-side SMPS systems, or CoolMOS™ product series for PSE-side SMPS systems), PoE is smart Buildings can play a very critical role in the construction of reliable ICT infrastructure. It can also create additional cost savings opportunities.

Figure 3: PD uses a general-purpose isolated DC/DC converter solution (above) that can only be used for specific applications such as LED lighting for power supply. PSE requires high-efficiency PFC and low-loss switches with isolated topologies (pictured below).

Example 2: Condition monitoring

Equipment and system failures such as elevators and air conditioners can cause serious interference and damage to the normal operation of the building. In interconnected smart buildings, even small problems may cause huge interference to the operation of the building. Therefore, building managers are eagerly looking for various methods to monitor the status of installed equipment and effectively predict failures to prevent them from occurring.

Sensors play a decisive role in equipment condition monitoring. Sensors installed inside or outside the equipment can collect data on various parameters reflecting the operating conditions of the equipment. For example, air pressure sensors are used for airflow monitoring in HVAC equipment, current sensors are used for current measurement in motor drives, and microelectromechanical system (MEMS) microphones are used for sound anomaly and vibration measurement. These sensors can detect deviations from the predetermined optimal state in real time.

Following the implementation of condition monitoring, the next most reasonable approach is to implement predictive maintenance. Through predictive maintenance, it is possible to estimate when the equipment is most likely to fail, so as to carry out proactive maintenance in a timely manner.

This trend was evident at this year’s AHR exhibition (American International HVAC and Refrigeration Equipment Exhibition) in Orlando, Florida, and may become the focus of the Frankfurt exhibition.

After clarifying this trend, Infineon will exhibit an end-to-end demonstration device for HVAC system condition monitoring and predictive maintenance at the Frankfurt exhibition. The demonstration device was developed by Infineon in cooperation with Klika Tech, an end-to-end IoT and cloud solution developer, and is supported by Amazon Web Services (AWS). It can demonstrate the use of sensors in smart building condition monitoring and predictive maintenance solutions In the potential.

The demonstration device focuses on the main problems of HVAC equipment-including airflow monitoring. It integrates many Infineon products listed below to ensure accurate and reliable data recording.

Sensing:

· XENSIV™ DPS368 Barometric Pressure Sensor

· XENSIV™ TLI4970 current sensor

· XENSIV™ TLV493D-A1B6 3D Magnetic Sensor

· XENSIV™ BGT24LTR11 24-GHz radar sensor

calculate:

· XMC™ XMC4800 IoT Amazon FreeRTOS Connectivity Kit

Safety:

· OPTIGA™ Trust X

By using sensor devices in Infineon’s XENSIV™ sensor product line, key components in HVAC equipment-such as compressors, fans, motors and filters-as well as overall system vibration can be monitored. The sensor can directly collect data related to the component. The collected data can be pre-processed locally by the XMC™ microcontroller, and then sent to the AWS cloud for information extraction and anomaly detection. Embedded hardware security solutions can escort the security of the entire data flow from the edge to the cloud.

HVAC equipment is only used as an example to illustrate how sensors can help achieve condition monitoring and predictive maintenance, thereby discovering more added value for building operators, tenants and equipment manufacturers. For other key subsystems such as elevators, valves, and lighting, related semiconductor solutions and advanced software intelligence can solve maintenance problems and provide insights.

Summarize

If building automation wants to achieve a phased leap, it must be able to use the information input by the sensor to trigger the actuator and realize the automation of decision-making in all sub-system areas. By building a vital bridge between the real world and the digital world, semiconductor solutions such as sensors, power management chips, microcontrollers, and security chips can lay the necessary foundation for the intelligentization of buildings. Thanks to advanced technology and intelligent interconnection solutions, today’s buildings can be transformed into self-perceiving, green and smart buildings in the future, thereby helping to solve the challenges brought to society by urbanization and climate change.

Infineon’s XENSIV™ DPS368 pressure sensor can perform airflow monitoring in HVAC systems. Because it is waterproof and durable ((IPx8), the pressure sensor can be used in the harsh environment of HVAC for data collection.

The Links: PM25RSB120 SKM300GB066D