How will future cars change component design?Enabling safe, sustainable and intelligent mobility

“As the automotive industry continues to evolve, vehicle intelligence continues to develop on the global road. The transition from internal combustion engine drives to hybrid and fully electric drives requires increasingly new and more complex components, such as one in advanced driver assistance systems such as automatic parking, or the ability to follow other vehicles on the move. series of applications.

“

As the automotive industry continues to evolve, vehicle intelligence continues to develop on the global road. The transition from internal combustion engine drives to hybrid and fully electric drives requires increasingly new and more complex components, such as one in advanced driver assistance systems such as automatic parking, or the ability to follow other vehicles on the move. series of applications. Flexibility to develop solutions for emerging automotive systems is a key issue, so the way automakers collaborate with component suppliers is also evolving.

The automotive systems of the future require advanced sensing capabilities. Whether the sensor is in the form of a camera, radar, lidar or laser, how these components are secured, packaged or sealed is critical to ensuring their optimum performance. The reliability of sensors is directly related to vehicle safety and global road public safety.

Here, we’ll highlight three examples of evolving automotive components: the integration of advanced functions, the benefits of simulation involving material properties, and the integration of vibration damping in control Electronic circuit boards. We will also take a closer look at the simulation process and how smart sealing solutions can play an active role in sustainability.

Component innovation and functional integration

Considering the extensive use of measurement (sensing) and regulating (control) electronics in the so-called future car, sealing components for such applications must not only possess the traditional sealing function, but must also meet a wide range of additional requirements and demands. Human-machine interaction and machine-to-machine interaction require fundamental changes in the products we deliver in the future, and there are many factors to consider.

In the field of autonomous driving, these factors include:

• Functional integration

• miniaturization

• Multi-part material combinations

• New materials combining different physical properties

• Multi-component manufacturing process

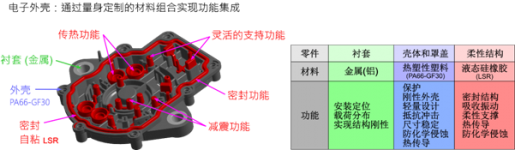

An example of a control electronics enclosure is given to highlight how these additional requirements can be integrated. This housing is usually made of thermoplastic material, which has a stable outer shell that protects sensitive internal components from environmental influences. In order to perform this function permanently, the material must have sufficiently high impact resistance and dimensional stability, especially high heat resistance and resistance to any media present (such as spray water, salt water, grease, mineral oil, fuel and cleaning agents) excellent corrosion resistance.

Depending on the application area, other requirements such as good thermal conductivity requirements, high electrical conductivity requirements for shielding from electromagnetic fields, or low density requirements for lightweight construction applications can also come into play. Since such enclosures are often part of larger assemblies, these housings must have integrated attachment points for mounting to surrounding assemblies. Injection-molded metal bushings are a great way to mount the housing on larger components in the engine bay, for example, as they form a stable attachment point to secure the housing to larger components in the engine bay, preventing the housing from becoming localized Plastic deformation, and ensure that the assembly forces generated during assembly can be uniformly transmitted and distributed to the housing.

Another key component of the enclosure is the elastomeric seal, which functions well beyond traditional sealing. Elastomers are typically based on liquid silicone (LSR) that covers the entire interior of the control electronics housing, forming complex three-dimensional flexible and elastic structures. In addition to ensuring a static seal between the housing base and the cover and protecting the interior, the elastic structure of the seal or sealing material holds the electronic components in place by means of cushioning elements. This suppresses damaging mechanical vibrations and significantly reduces the dissipation of thermal energy into the environment from operating electronic components.

Figure 1: Electronic housing: functional integration through a combination of tailored materials

Minimize development costs

The most important applications of elastomeric materials, especially in sealing, are based on their superelastic mechanical properties. For housings for electronic devices or sensors, the elasticity of elastomers ensures that sealing pressure is maintained over long periods of time and over a wide temperature range, providing the necessary flexibility in compensating for design tolerances, saving production costs. In many modern applications, such as in autonomous driving, it is especially important to combine different physical material properties to achieve functional integration. In addition to elasticity, these elastomeric materials must have other additional physical properties:

• Hyperelasticity

• flexibility

• Viscoelasticity

• Mechanical damping characteristics

• Optical transparency within a specified frequency range (or wavelength range)

• Conductivity

• Thermal Conductivity

• insulating or magnetic

These combinations of properties can be achieved through specially synthesized novel polymer materials to meet specific requirements. However, the development of this material is time-consuming and expensive, requires expertise and synthesis equipment, and the properties achieved may still be quite limited.

Often, desired additional material properties can be achieved more efficiently by incorporating special fillers into the elastomer matrix – a method well known to elastomer manufacturers. Depending on the type of filler, particle size distribution, particle shape and particle concentration, the desired material properties can be tailored to customer needs while simplifying a process that is often labor-intensive.

Simulation can support the development of this class of materials with new properties and provide a good opportunity to calculate and predict the effect of fillers in polymer matrices. This has accelerated the development of such multiphase or layered materials. Create models of material structures based on existing materials or ideas for new materials. Based on this so-called representative volume element (RVE) and the intrinsic properties of the components (matrix and filler), finite element analysis can be used to calculate desired properties, such as thermal conductivity or elastic behavior. Therefore, the composition of new materials can be optimized at an early stage, which can greatly reduce subsequent laboratory work.

Figure 2: Simulation supports development of layered materials with new properties

Ensure vibration damping of the control electronics board

In addition, for specific applications, the viscoelastic material properties of the elastomer play an important role, especially the damping properties. Certain damping properties of the material may be required to prevent the assembly from vibrating too much during driving and under resonance conditions. An example of such an application is the integration of shock absorbing elements into printed circuit boards of electronic circuits. In the examples below, the board geometry is used to provide the necessary flexibility in the overall design for a specific application. The integrated LSR structure provides the necessary flexibility while providing damping to prevent damage due to amplitude expansion in resonance situations. The sensing and/or control electronics are housed in the housing, and in order to perform their function reliably, it is necessary to mechanically separate them from the housing and vehicle vibrations.

Figure 3: Influence of geometric design and material properties on resonance characteristics (simulation results of sensor electronics)

Consider simulation early in the product development process

The development of new components and parts for next-generation vehicles can be an expensive and time-consuming process. Here, in order to eliminate the need for multiple single-mode development, the associated testing and analysis, partnering with a specialist component supplier well versed in simulation can greatly speed time-to-market while reducing capital expenditures during the development phase and beyond.

If we look at the simulation process itself and how it facilitates the development of new parts and their components, the end goal is to design, visualize and optimize virtual concepts and then support their translation into real products and processes. By combining CAD tools (providing geometry) with simulation tools to create virtual models of specific parts, it is possible to accurately work out their function before they are built.

After CAD, as part of the modeling phase, we have to assign specific material properties to different parts of the assembly. Therefore, a series of tests must be performed and then the necessary materials must be modeled. This is an important prerequisite and is usually only available through specialist component manufacturers.

For many applications and products, experienced suppliers use their own tailor-made materials, so customers cannot obtain detailed material information from outside. Therefore, suppliers need well-equipped in-house teams capable of undertaking all testing and mathematical modeling of these materials for simulation. These teams, in turn, can provide testing and modeling services to clients, providing additional support throughout the process.

When it comes to part function and design, finite element method-based structural-mechanical calculations allow fine-tuning of sealing element properties and optimization of their performance and design, allowing rapid development of first drafts into convincing design proposals. Many aspects and influencing factors need to be considered – firstly the given installation space, the effect of the applied load (eg displacement, pressure or temperature), and the properties of the materials used. The most important thing is to ensure that at -40°C (-400F) to +150°C (3020F) function and seal integrity over the temperature range, taking into account all design tolerances.

It is also necessary to carefully observe how the material behaves during production, so end-flow analysis is highly recommended. All details of the molds used, from mold filling to optimizing thermoplastic and elastomer molding processes, can be analyzed, effectively simulating the entire manufacturing process, including details such as thermal management of the molds used and mold temperature distribution to ensure consistent quality.

The benefits to customers of product development in a partnership with a supplier are clear, especially for sealing applications. Sealing performance is often the last element considered in the design, and because it is implemented too late, the problems that can arise are numerous and varied, often requiring a solution that is not the best design option. All of these dimensioning problems can be easily solved in the development stage with the corresponding design freedom, but it is much more difficult to solve in later stages after the design of some components or important parts of the system has been frozen. By involving suppliers and applying their specific knowledge early in the development process, it is possible to optimize the design from the outset to ensure that global rather than local optima are achieved.

Incorporating sustainability into future mobility solutions

One of the main concerns of electric vehicles is to have a positive environmental impact, and here, the processes involved in component development can help achieve these goals. Sustainability starts with materials and continues to evolve as the component development process evolves. By optimizing the processes mentioned above and the designs that are intended to be produced, in some cases, the development team can actually reduce the amount of material required to deliver optimal performance.

From a design perspective, engineers specializing in sealing components are always looking for ways to integrate bio-based materials, and they should have the ability to develop tailor-made materials from scratch to meet the specific needs of their customers. Ideally, they will also have in-house compliance experts who can work with materials experts to remove critical substances and identify those that may become obsolete under requirements such as Registration, Evaluation, Authorization and Restriction of Chemicals (REACH). If they find a material that might be tight in the future, it won’t be used to develop the material. The right supplier should be your indispensable partner to stay ahead – designing materials that meet future as well as current regulatory requirements.

In terms of environmental sustainability, smart sealing solutions can also have a positive impact. A sensor-active layer within the elastomer can detect force, touch and even leaks, and in some cases the presence of media on the sealing surface, improving predictive maintenance capabilities. This is a much-needed feature in battery packs, for example, any form of leakage can result in reduced functionality or even overheating.

When integrated into a sealing solution, electronic components such as chips and sensors can also detect factors such as temperature and pressure. If we take the example of a battery pack again, monitoring thermal conditions is critical, as optimal functionality can only be achieved within a specific temperature range. The ability to monitor component status is not just for the driver of the vehicle, but for the entire system, so service or maintenance can be scheduled when it is actually needed, rather than guesswork at intervals.

Ultimately, the cars of the future will be markedly different from those with internal combustion engines we are familiar with today. From the perspective of end users, the essence of the car, that is, the way to travel from A to B, has not changed, but as technology develops towards fully autonomous vehicles, beneath the surface, the world is changing. Therefore, the way of cooperation between manufacturers and their suppliers must change, and there should be more focus on the way of cooperation in joint research and development, and these future visions will be realized with unprecedented speed and efficiency.

The Links: RM500UZ-M 6DI15S-050