Analysis of the development trend of automotive clock technology, although the device is small, it has far-reaching influence

“Automotive electronics are evolving faster than ever, especially as manufacturers introduce feature-rich infotainment systems and advanced driver assistance systems (ADAS) into their product lines while also developing fully autonomous vehicles. Advanced semiconductor technology is helping the rapid development and deployment of these new vehicle systems.

“

Today’s stringent clock requirements in automobiles have created new requirements for clock generators, as follows:

1. The number of precision reference clocks required in automotive electronics is increasing, resulting in increased system design complexity and changing design approaches.

2. Changing clock requirements from quartz to silicon has multiple benefits.

3. The integration of reference clocks into a simplified clock tree has multiple benefits.

4. Silicon-based timing devices can provide flexibility to system designers and help them meet safety requirements.

Automotive electronics are evolving faster than ever, especially as manufacturers introduce feature-rich infotainment systems and advanced driver assistance systems (ADAS) into their product lines while also developing fully autonomous vehicles. Advanced semiconductor technology is helping the rapid development and deployment of these new vehicle systems.

In this regard, semiconductor manufacturers are bringing more automotive-grade products to market, including higher-bandwidth processors, GPUs, high-speed PCI Express switches, Ethernet switch SoCs/PHYs, and FPGAs. The adoption of the latest generation of automotive-grade IC platforms and connectivity solutions has greatly improved system functionality, functionality, performance and cost, but has also created new design complexity challenges for system designers.

One of these challenges is ensuring the high accuracy, and therefore the growing demand for low jitter reference clocks in processors, FPGAs, switching SoCs, Ethernet PHYs, USB PHYs and high-speed SerDes in PCIe Express Gen3/4 nodes. All of these devices are quickly making their way into automotive gateways, infotainment systems, digital cockpits, ADAS, LiDAR and autonomous driving control units.

As the functionality and sophistication of automotive electronics increases, so does the number of precision reference clocks required for these systems. As a result, system designers have borrowed solid timing design best practices from the computing and communications markets, and silicon-based timing solutions have been the preferred solution for decades.

The evolution from quartz to silicon is underway

Historically, automotive system designs have used lower bandwidth processors and microcontrollers, requiring only one or two single-ended reference clock frequencies per board-level design. Meeting these timing requirements is very simple because they only use one or two quartz crystals or crystal oscillators.

With the increasing number of reference clocks in modern automotive Electronic designs, the easiest way to meet timing requirements is to simply add more quartz crystals or oscillators. However, scaling the number of quartz parts has many disadvantages and limitations. Generally, quartz crystals and oscillators are the components with the highest failure-in-time (FIT) in automotive designs, so adding more of these components is very bad for system reliability reasons.

For years, the communications, computing, industrial and consumer markets have used silicon-based integrated clock generator solutions to replace quartz crystals and oscillators for their precise reference clock timing requirements. As processor speeds and transceiver bandwidth levels increase, jitter requirements on the reference clock become increasingly difficult to meet.

The latest generation of automotive gateways, ADAS sensors and autonomous driving platforms are using high bandwidth processors, FPGAs, 1G/10GbE connections and PCI Express Gen3/4/5 data buses that require differential clocking with less than 500fsRMS phase jitter.The clock generator can combine the functionality of up to eight quartz crystals or oscillators into a single IC and provide excellent RMS phase jitter performance on the clock output (simplifying the clock tree reduces points of failure

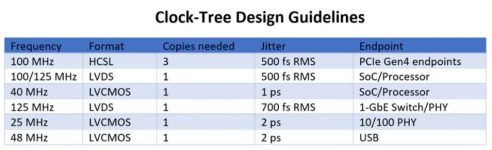

Selecting and defining the best timing solution is simplified by aggregating the set of reference clocks required in a system design. A set of reference clocks is often referred to as a “clock tree”. The clock tree typically includes the input reference frequency, the output clock frequency required by the endpoint, the clock output format level, and the maximum jitter performance level for each reference clock, which is usually specified by each endpoint device manufacturer (see table).

In addition to new automotive processor, FPGA, connectivity and data bus semiconductor solutions hitting the market, AEC-Q100 qualified silicon-based timing solutions are now available to simplify clock tree design complexity in automotive applications. By incorporating a reference clock into an integrated clock generator, system designers can reduce points of failure, improve system reliability, and realize significant benefits in jitter performance and frequency flexibility. Other benefits include reduced board area, lower cost, and more.

Clock generators offer integration, cost and reliability advantages over traditional quartz-based solutions.

Solve safety problems

With the introduction of ISO26262 and ASIL requirements, safety has always been at the forefront of all automotive electronics designs. Designing to these new standards may also present new challenges. Silicon-based timing devices can meet system safety levels by providing redundant primary and backup reference input functions, health monitoring functions, and interface with ASIL rated MCUs or fault detection indicator pins for system safety interfaces.

In the past, automotive electronics system designers have been reluctant to use clock generators because long traces may fail to meet CISPR25 Class 4 or 5 limits due to electromagnetic radiation. Spread spectrum has always been a common feature to reduce EMI, but there are a large number of cases where reference clocks cannot tolerate the error effects of spread spectrum.

System designers can now overcome these design challenges with complementary LVCMOS output drivers that are available in the latest generation of AEC-Q100 qualified clock generators with EMI levels within CISPR25 limits.

As automotive electronics technology continues to evolve and grow in complexity, semiconductor suppliers offer more new AEC-Q100 devices, which are only available in industrial temperature grade options. The latest generation of AEC-Q100 qualified clock generators maximizes flexibility and programmability, enabling system designers to roll out fully customized solutions for specific clock tree requirements in minutes without having to Wait for long development cycles for custom products. If changes are required during product development, they can be easily made through user-friendly software or directly in the system using the I2C port.

in conclusion

To improve passenger safety and experience, automakers are rapidly adopting new networking, ADAS, and autonomous driving systems that utilize advanced semiconductor processors, FPGAs, GPUs, and Ethernet switches/PHYs. New platforms with these higher bandwidths increase design complexity, increasing the need for high-accuracy, low-jitter, single-ended and differential reference clocks.

The introduction of the automotive-grade AEC-Q100 clock generator provides designers with an integrated, high-performance solution capable of consolidating an entire clock tree into a single IC, while offering improved performance compared to traditional quartz-based crystal and oscillator solutions Improve reliability and reduce system cost.

The Links: DMF-50383NF-FW KCB104VG2BA-A21